Adhesive Tapes & Speciality Materials

Our unique combination of coating capabilities and innovative technical teams drives the development of custom, multi-functional materials for specific end uses.

Adhesive Tapes & Speciality Materials

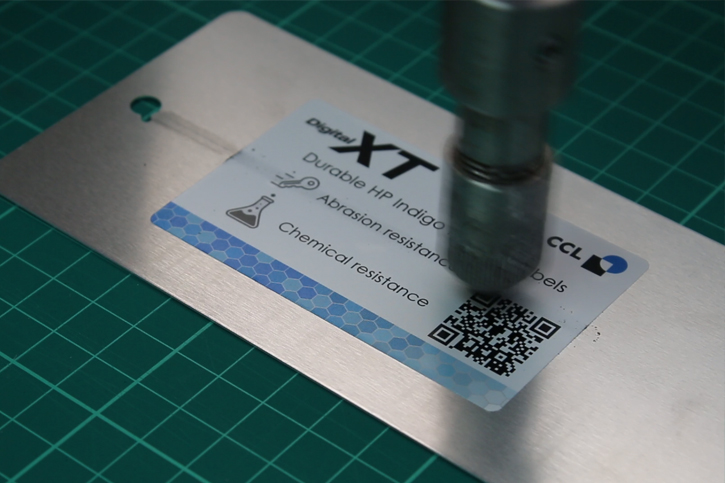

- Polyester and polypropylene-based materials with custom topcoats and adhesives that have exceptional durability, performance and print quality.

- Typically used for marking and identification labels

- UL- and cUL-approved materials

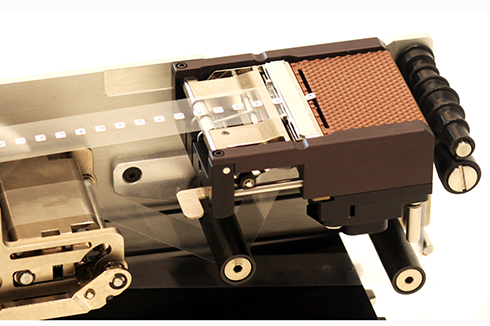

- Additional information can be printed using thermal transfer (POD) technology

High Performance Labelstock

- Polyimide-based materials with unique topcoats that have high temperature resistance and excellent print quality, designed for use in printed circuit board assembly.

- Designed to withstand harsh environments

- Abrasion, heat and chemical resistance

- Suitable for top and bottom-side PCB assembly, where tracking is required throughout the manufacturing process

High Temperature Materials

- Polyester-based materials embedded with overt, semi-covert and covert security features.

- Labelstock includes tamper-evident features of voiding and destructibility

- Used in box seals and other secure packaging applications

- Embedded features allow brand owners to identifity counterfeit goods, and products that have been tampered with

Security Application Materials

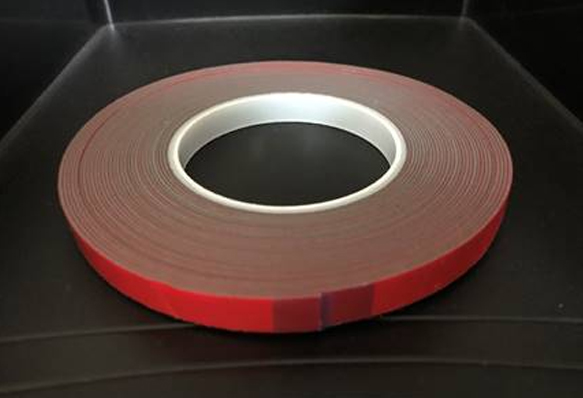

- Double-sided protective and transfer tapes utilising acrylic, rubber and silicone adhesives.

- Used for fabrication and protection within electronic devices

- Applications include lamination, bonding, positioning, rework and protection

- Designed to create multi-layer constructions that address specific customer requirements

Adhesive Tapes

- CCL Olympic acrylate-based thermally conductive materials are used to provide a preferential heat transfer path away from heat generating components.

- The very soft acrylic composition allows a low load during compression, and it provides a tacky surface for optimal contact to any substrate.

- The non-silicone based products are ideal for automotive and electronic applications.

- Can be customized to optimize softness, tack and thermal conductivity

Thermal Tapes & Pads

- CCL Olympic acrylic foam tape materials are engineered to provide a high performance bonding solution throughout a wide variety of applications

- Offers a cost effective solution within many sectors including consumer electronics, automotive and industrial

- Key features: High bond strength, chemical resistance, impact resistance, waterproof to IPX8

- Low surface energy (LSE) options available.

- CCL Olympic also offers customisation of key features to suit complex applications

Acrylic Foam Tapes

Materials Science Capabilities

- In-house formulated topcoats and adhesives

- Water and solvent-based formulations

- In-line filtration

- System-controlled formulations and manufacturing procedures

- Allows for double-sided printing and printing onto adhesives

- Combines with complex in-line cutting to enable slitting, perforating, back cutting and security cuts

- Allows labels to be supplied in rolls, sheets, fan-folded packs or bobbin-wound formats

Formulation Preparation

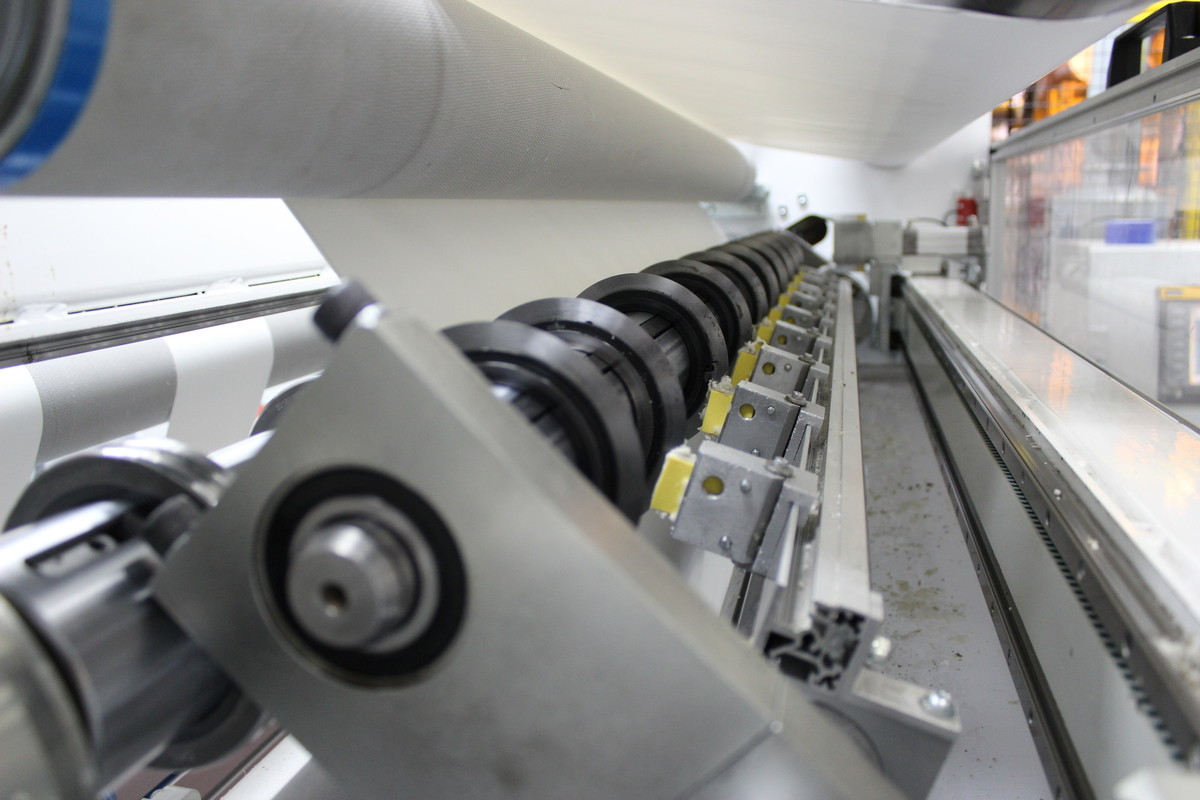

- Direct and transfer coating methods

- Wide web coating

- Reel-to-reel handling of polyester, polyimide, paper and polyolefin

- In-line corona treatment to enhance surface receptivity

- Water-based acrylic adhesives

- Hot melt rubber adhesives in-line

Coating

- Advanced slitting capabilities allow for materials to be prepared for further processing at CCL Design conversion sites

Slitting

Typical Slitting Parameters;

- Automatic blade setting

- Minimum slit width: 25mm

- Maximum slit width: 1300mm

- Unwind 1 tonne / 1m outer diameter

- Maximum slit coil 800mm outer diameter

- Automated reel ejection system

- Two side contact web cleaning

- Anti-static control

- Delicate materials are transfer laminated off-line on customised equipment, allowing for one- or two-sided adhesive lamination

- Fine tension control

- In-line corona treatment to enhance surface receptiveness

- In-line, anti-static treatment

- Differential release liners for process aid

Wide Web Lamination

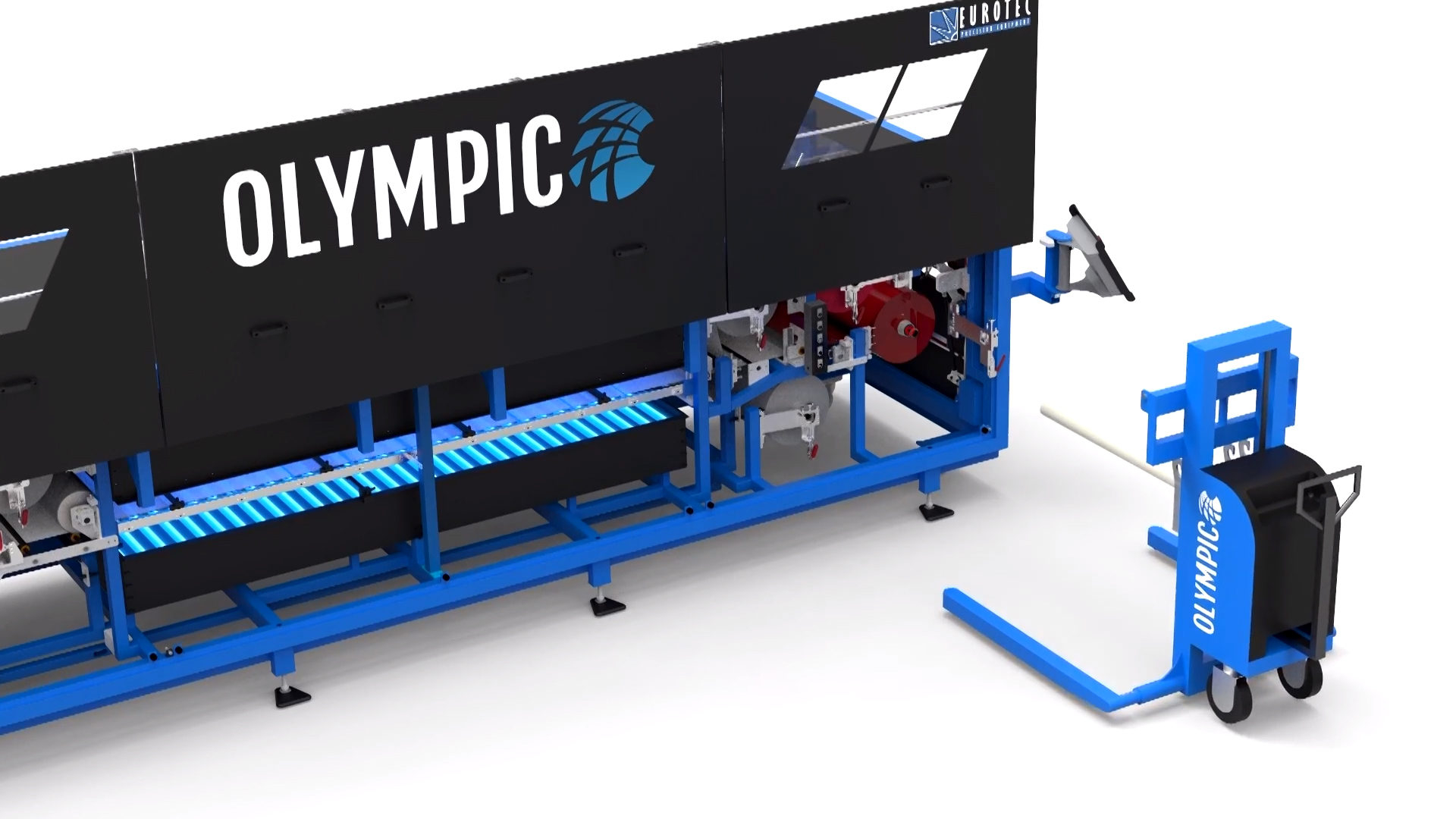

- CCL Olympic has a unique process to produce acrylic foam tapes as well as thermally conductive tapes and pads

- The highly specialised machinery uses UV technology to produce products free from solvents and silicones

- Our in-house experts can customise the product’s performance to achieve high performance in a variety of criteria

Acrylic Foam Tape Manufacture

R&D Laboratories

CCL Design Materials Science has state-of-the-art R&D facilities in East Kilbride (UK), Suzhou (China), Venray (Netherlands) and Clinton (US) where products are developed for electronics, industrial and automotive applications. Together with global CCL partner laboratories, which offer surface, structural and molecular analysis, these laboraties provide:

Coating and formulation design

Laboratory prototype constructions

Performance testing to customer and industry standard specifications

Proven scale up to production process

CCL Design Olympic Bonding Solutions

CCL Olympic are a specialist manufacturer of pressure-sensitive acrylic foams. Based in Venray, the Netherlands, CCL Olympic specialises in the following:

- Acrylic foam tapes

- Thermal conductive tapes and pads

- Electronic tapes

- Custom solutions

Product Development and Testing Capabilities

CCL Design labs are equipped with the very latest material development technology, and testing processes include:

- Abrasion and wear testing

- Anti-reflection coatings reduce light lost

- Peel adhesion testing

- Thickness measurement

- Impact testing

- Conductivity / resistivity testing

- Weathering to automotive industry standards

- High resolution surface and structural analysis

- Mechanical performance

- Barrier properties

- Print performance

- Digital conversion